Construction sites are inherently dangerous places, with workers facing a multitude of risks every day. Falls from height are a significant hazard in the construction industry, and one of the most effective ways to prevent these accidents is through the use of safety nets.

Safety nets are a vital piece of safety equipment that can help protect workers from falls and reduce the severity of injuries if a fall does occur. These nets are typically made from high-strength materials such as nylon or polypropylene, and are designed to catch falling objects or people and prevent them from hitting the ground.

There are two main types of safety nets used in construction: debris nets and personnel safety nets. Debris nets are used to catch falling tools, materials, or debris, while personnel safety nets are designed to catch workers in the event of a fall.

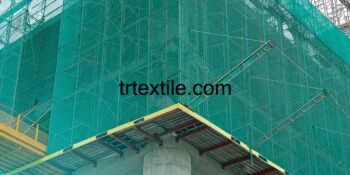

Debris nets are typically installed around the perimeter of a construction site or around specific areas where work is being carried out at height. These nets are designed to prevent objects from falling onto workers below, reducing the risk of injury or fatality. Debris nets are also commonly used to contain dust, debris, and other materials that could pose a hazard to workers or the public.

Personnel safety nets are typically installed below areas where work is being carried out at height, such as on scaffolding, bridges, or roofs. These nets are designed to catch workers in the event of a fall, reducing the distance they fall and the severity of their injuries. Personnel safety nets are typically installed with a fall arrest system, which includes harnesses, lanyards, and anchor points to secure workers to the net.

In addition to preventing falls and reducing the severity of injuries, safety nets can also help to improve productivity on construction sites. By providing workers with a safe working environment, employers can help to reduce the risk of accidents and injuries, leading to fewer delays and disruptions to work schedules.

It is important for construction companies to ensure that safety nets are installed correctly and regularly inspected and maintained to ensure they are in good working order. Nets should be installed by trained professionals and regularly inspected for any signs of wear or damage. Any damaged nets should be repaired or replaced immediately to ensure they continue to provide adequate protection for workers.

In conclusion, safety nets are a crucial piece of safety equipment in the construction industry, helping to prevent falls and protect workers from injury. By investing in high-quality safety nets and ensuring they are installed correctly and regularly inspected, construction companies can help to create a safer working environment for their employees and reduce the risk of accidents on site.